Cleaning laser pulsed

Cleaning laser pulsed

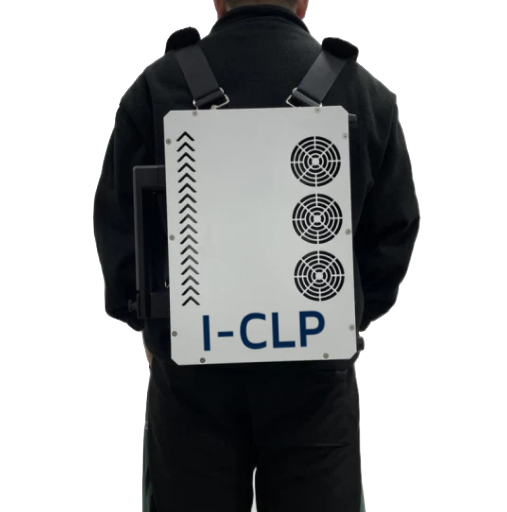

I-CLP. Innovation in laser cleaning

Precise, efficient and safe cleaning with pulsed laser technology

Give us your contact information and receive professional advice without obligation.

I-CLP: The laser cleaning revolution with pulsed laser technology

I-CLC: The laser cleaning revolution with pulsed laser technology

The I-CLP is an innovative laser designed for selective cleaning of parts and surfaces, taking advantage of pulsed beam technology. This advanced technology allows to overcome the ablation threshold of contaminants such as paint, rust or varnish, without damaging substrates such as metal, wood or glass. Unlike other methods, I-CLP does not significantly heat the material, ensuring safe and controlled cleaning.

Versatility and Applications in diverse Industries

Automotive: Cleaning of welds and preparation of surfaces to improve paint adhesion.

Aerospace: Removal of coatings without damaging critical components.

Heritage Conservation: Restoration of monuments and works of art without altering the original surfaces.

Heritage Conservation: Restoration of monuments and works of art without altering the original surfaces.

Medical industry: Preparation and cleaning of medical devices and implant surfaces.

Molds and tools: Disposal of residues in industrial molds and precision tools.

Thanks to its adjustability, the I-CLP offers selective cleaning, reducing maintenance times and increasing part life. With a design that meets strict safety standards, this laser is ideal for any industry looking for precision, efficiency and reduced environmental impact.

Receive in your email the dossier with the complete technical information