24h non-stop ink filtering

Laser anilox roll cleaning system

I-MIF Magnetic filter

Give us your contact information and receive professional advice without obligation.

I-MIF filters out all debris flowing in the ink

SAVING 80 % OF TIME

ALVEOLS AT 100% PERFORMANCE

ANILOX CLEANING WITH OR WITHOUT SHAFT

LASER OPTIMIZED FOR FLEXOGRAPHY

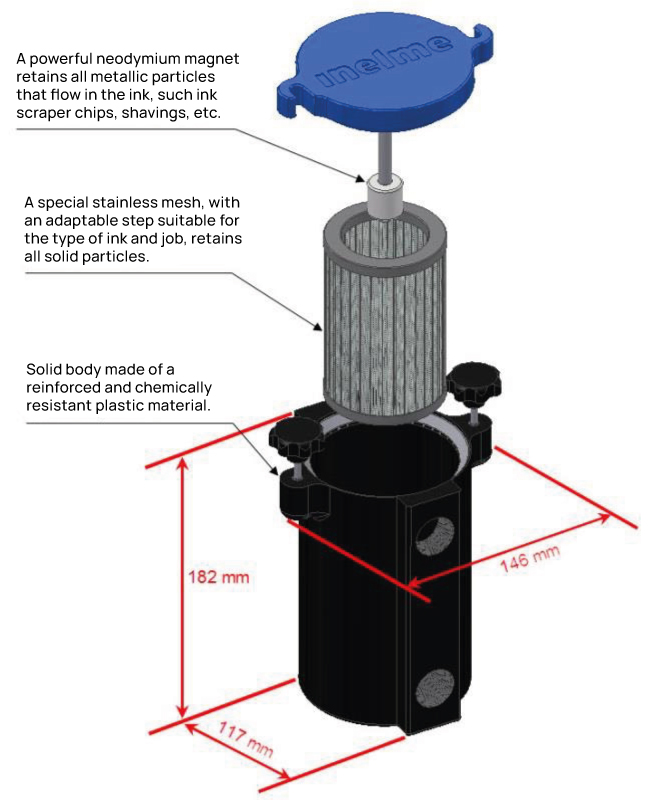

During the printing process, solid dirt falls into the ink, directly affecting the quality. printing and causing damage to printer parts. Dust, small parts of the blade, ink, etc. dry, cellulose gum, wooden sticks…

I-MIF ink filter extends the life of printing equipment

By preventing these solid particles from entering the ink circuit, we obtain a much more consistent ink and thus avoid printing errors such as “ghost prints” due to dust on the surface and scratches or damage to the anilox, chambers or piping.

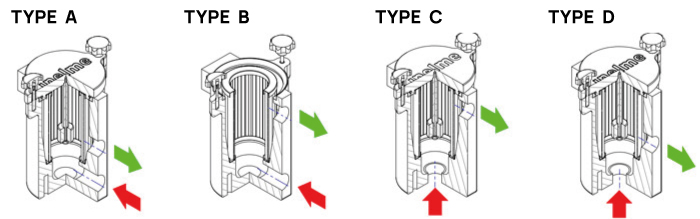

I-MIF is very easy to mount and has a size that allows it to adapt to any equipment. It can be supplied with ink inlet and outlet in different positions with 1/2“, 3/4” thread.

The system incorporates a pressure sensor at the filter inlet that detects when the filter has too much dirt and is about to clog the ink flow to automatically divert the flow to a second filter (possibility of installing three or more in series).

Up to 80% time savings when cleaning Anilox cylinders with I-Lac machines

Cleaning anilox cylinders has always been one of the biggest concerns for flexo printers. If the cylinders are not perfectly clean, their transfer capacity is reduced and therefore the color intensity of the print is lost, with the consequences for the production that this can have: invalid prints, longer start-up times, etc. I-LAC solves this problem effectively thanks to the laser that removes the dried ink from the inside of the cells without damaging the cylinder cells. A specially designed optical laser vaporizes any residue and cleans away dried ink, adhesives, waxes, silicones, etc. Laser technology allows cleaning without exerting any mechanical or thermal action on the anilox cylinder, which allows us to clean even after each use and preserve the useful life of the anilox rollers for much longer.

We have I-LAC machines with measurements from 500 mm in length to 3500 mm (cylinder without shafts), and special measurements can be adapted according to needs.

|

Model |

Maximum cleaning length (cylinder without shafts): |

Minimum cylinder diameter: |

Maximum cylinder diameter: |

|

I-LAC F60- 6 |

600 mm |

Ø55 mm |

Ø200 mm |

|

I-LAC F60 – 10 |

1000 mm |

Ø110 mm |

Ø300 mm |

|

I-LAC F60 – 15 |

1500 mm |

Ø110 mm |

Ø300 mm |

|

I-LAC F60 – 20 |

2000 mm |

Ø110 mm |

Ø300 mm |

|

I-LAC F60 – 25 |

2500 mm |

Ø110 mm |

Ø300 mm |

|

I-LAC F60 – 30 |

3000 mm |

Ø110 mm |

Ø300 mm |

|

I-LAC F60 – 35 |

3500 mm |

Ø110 mm |

Ø300 mm |

Receive in your email the dossier with the complete technical information

Receive in your email the dossier with the complete technical information

I-MIFMAGNETIC FILTER

24h non-stop ink filtering

Improve the quality of your work in an easy way.

Discover the advantages of the Ink Filtering System.

The system incorporates a pressure sensor at the filter inlet that detects when the filter has too much dirt and is about to clog the ink flow to automatically divert the flow to a second filter (possibility of installing three or more in series).

Receive in your email the dossier with the complete technical information

[gravityform id=”25″ title=”true” description=”true”]