Solvent-based glue mixer for lamination

Solvent-based glue mixer for lamination

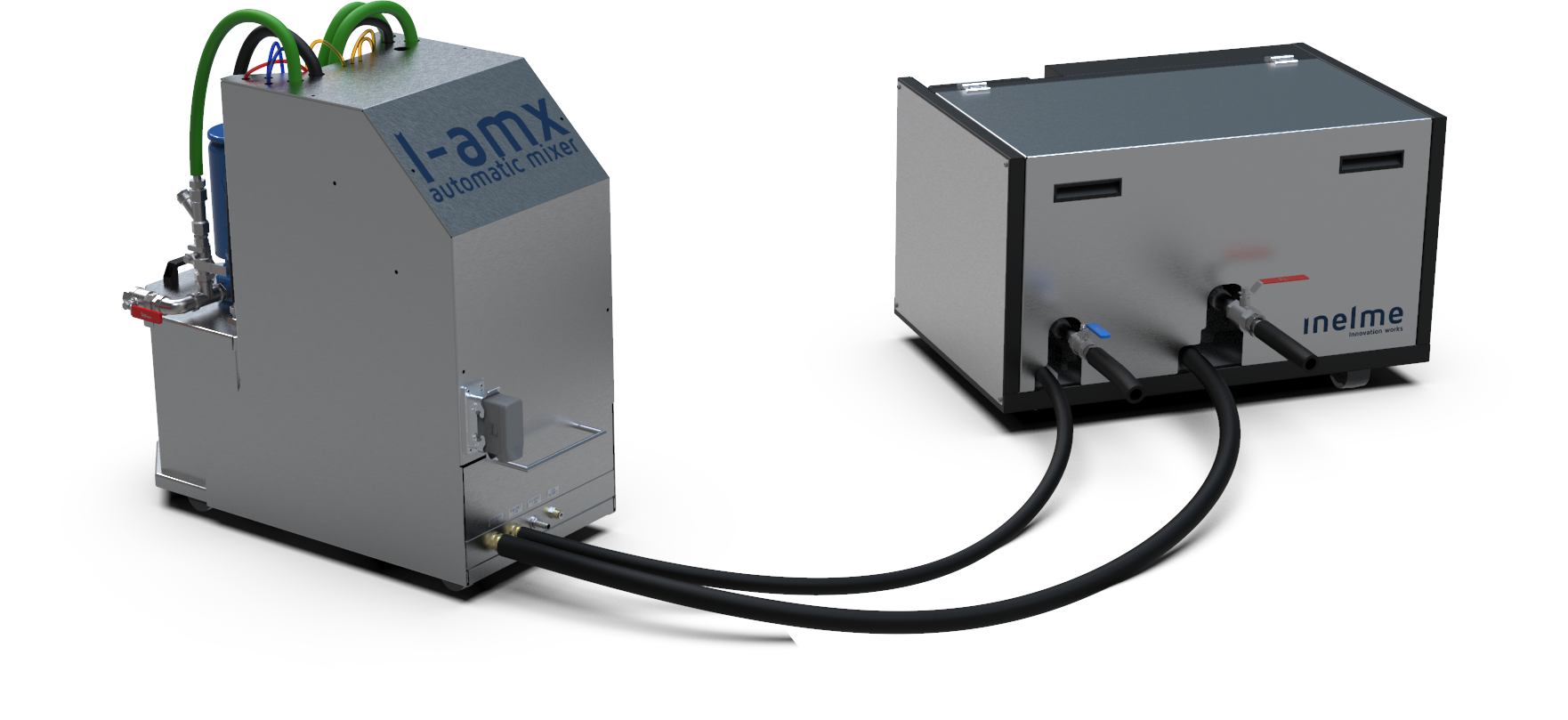

I-AMX MC-V Adhesive mixer for solvent lamination

Maintain viscosity in every application with our innovative mixer.

Give us your contact information and receive professional advice without obligation.

Advantages of the I-AMX MC-V solvent laminating adhesive mixer

Receive in your email the dossier with the complete technical information

Receive in your email the dossier with the complete technical information

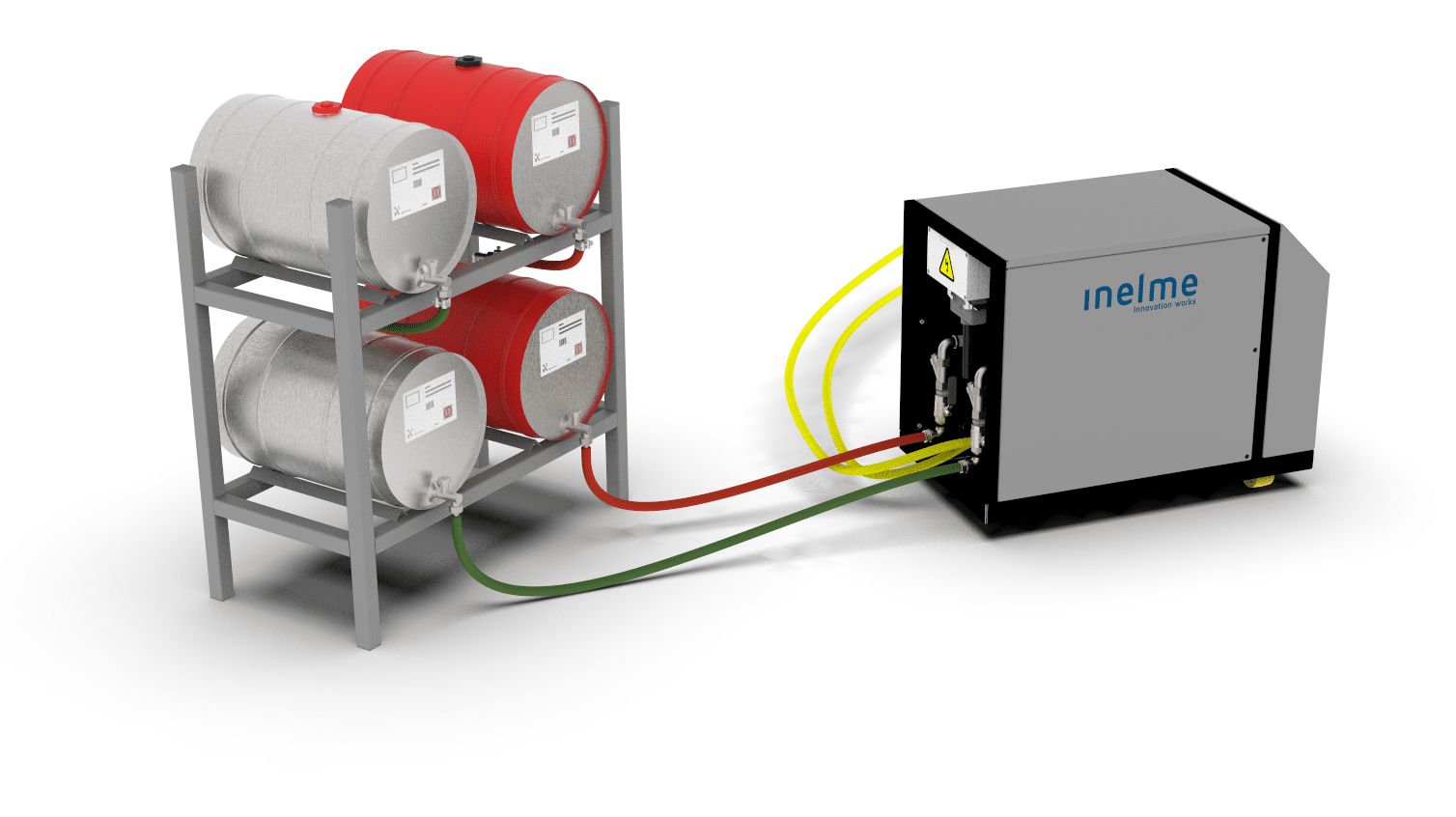

The I-AMX MC-V is a solvent-based adhesive mixing equipment designed for lamination, working with a two-component system. This equipment is distinguished by incorporating a compact mixing tank that is automatically filled with small amounts of adhesive, resulting in less than 5 kg of leftover at the end of the job. In addition, the time between mixing and application is minimal and constant, significantly improving the efficiency of the process.

The mixer is equipped with an advanced viscometer that monitors the solvent ratio, ensuring that the viscosity of the mixture remains constant. This system performs automatic wash cycles that prevent the build-up of catalyzed adhesive, reusing the solvent for both washing and dilution of the adhesive.

The main chassis houses the metering pumps, flowmeters and motors, all controlled by software that allows selecting the desired viscosity, operating in manual or automatic mode, and setting warning alarms. The mixed glue and solvent tanks are equipped with level sensors and supply pumps, ensuring accurate and efficient control.

Notable features include: