Solvent-free glue mixer for lamination

Solvent-free glue mixer for lamination

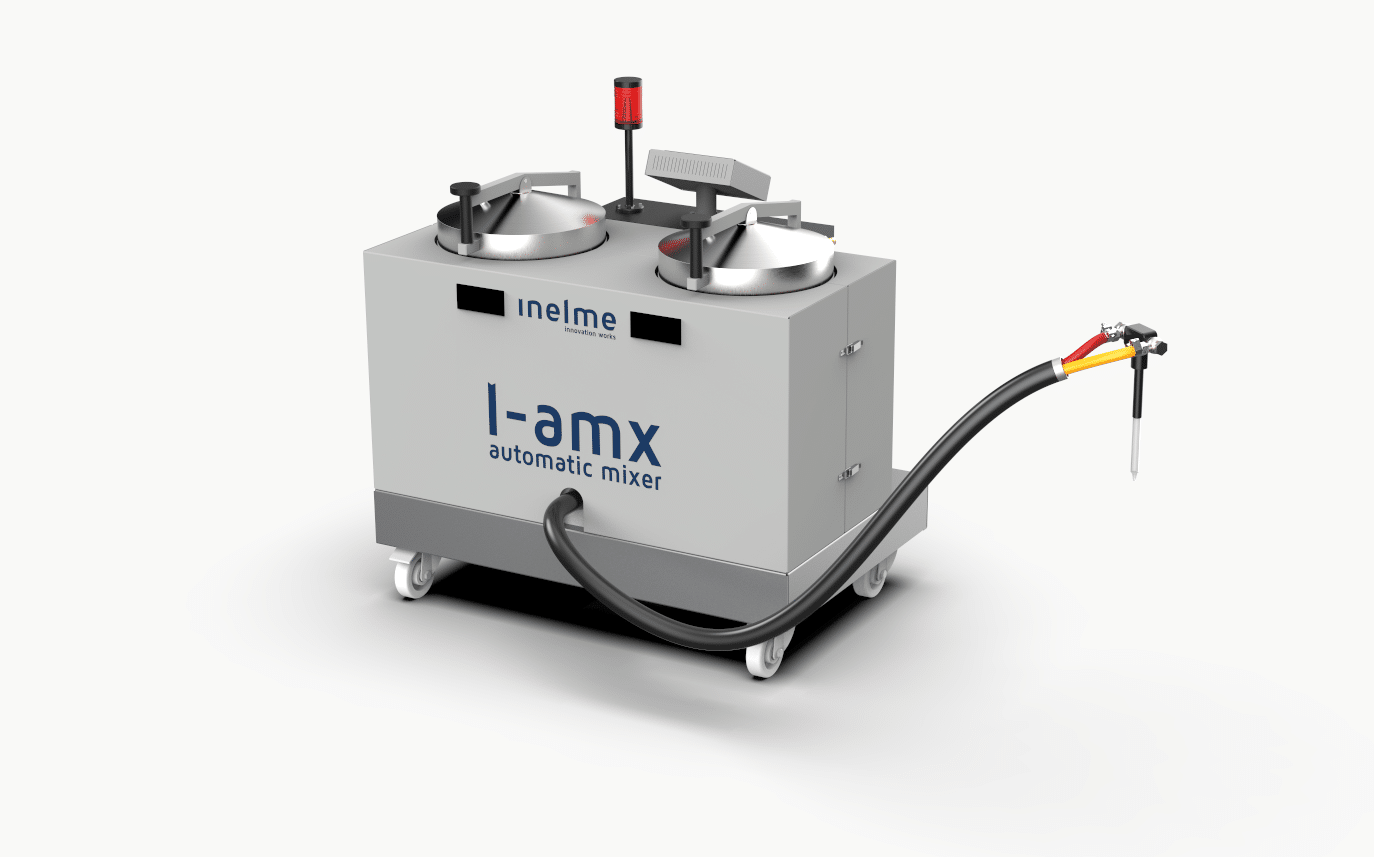

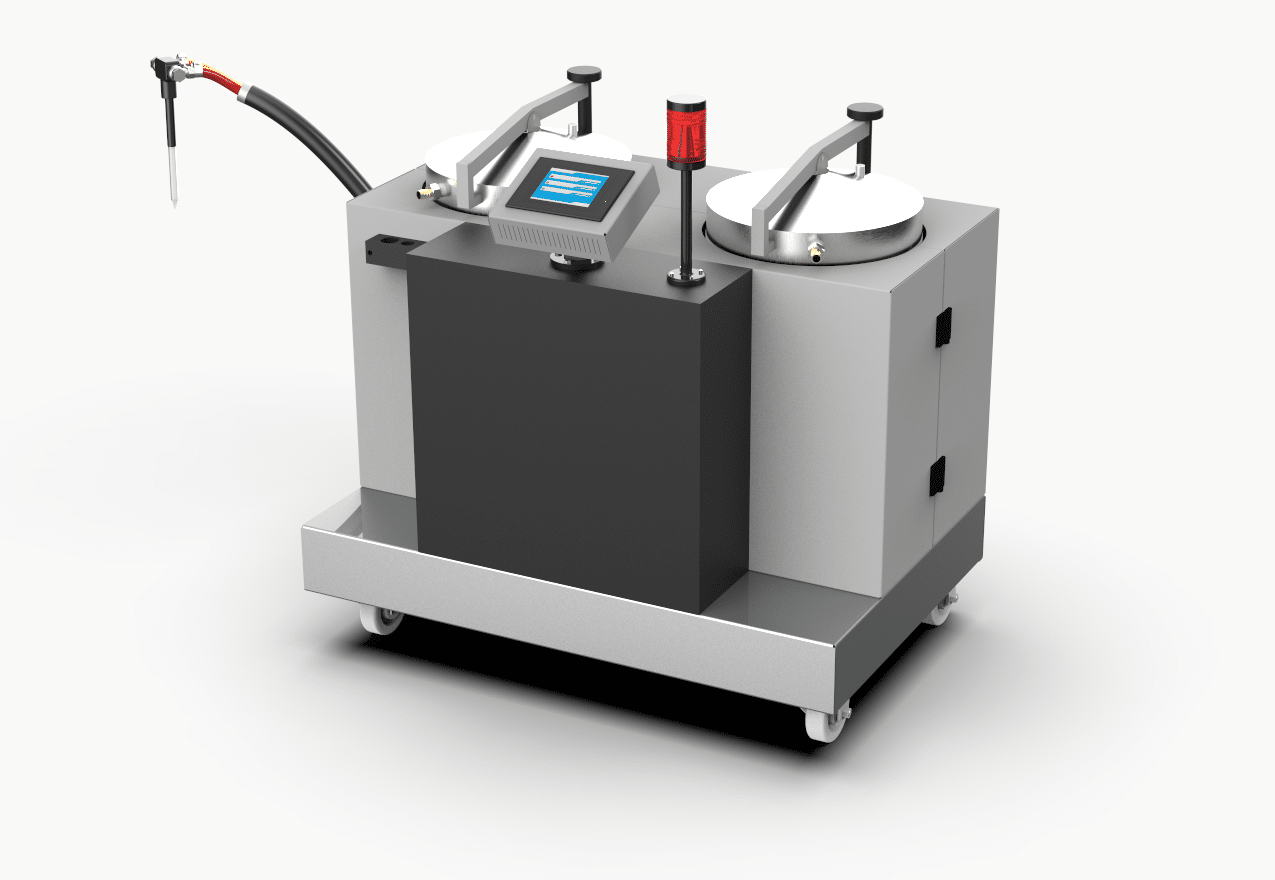

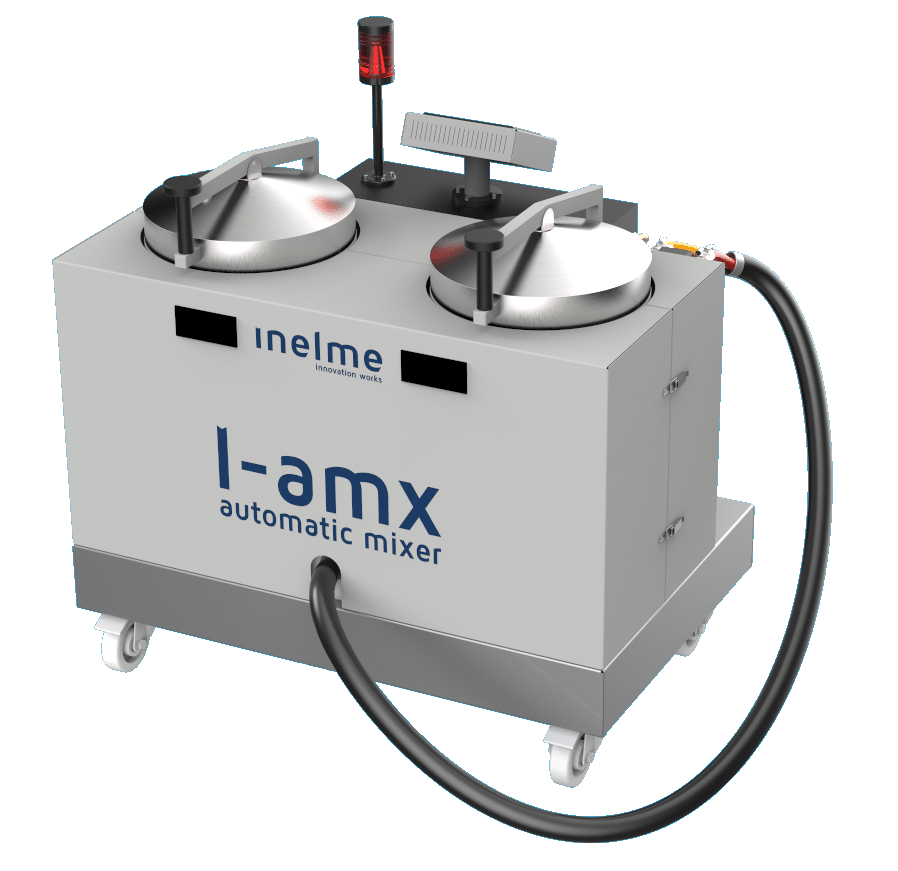

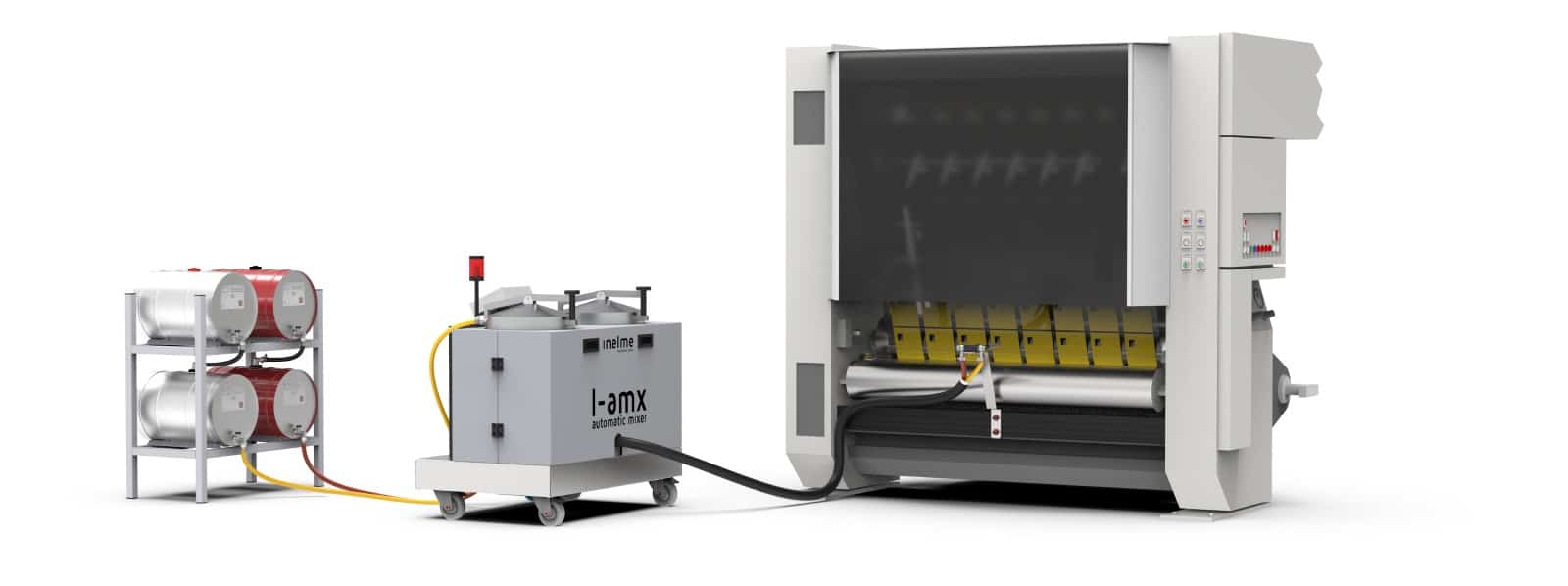

I-AMX. Adhesive mixer for lamination

Maximum precision and efficiency in mixing solvent-free adhesives for lamination. Compact, easy to use and highly customizable.

Give us your contact information and receive professional advice without obligation.

Advantages of the I-AMX Adhesive Laminating Adhesive Mixer

Receive in your email the dossier with the complete technical information

Receive in your email the dossier with the complete technical information

The I-AMX is an advanced solvent-free adhesive mixing equipment specifically designed for lamination. Available in three versions: without its own tanks, or with 30 and 60 liter tanks for both glue and catalyst, all equipped with heating systems. Mixing accuracy is guaranteed by flow meters, and a heated hose delivers the mixture directly to the application nozzle.

The system operates by means of volumetric gear pumps, controlled by geared motors and variable frequency drives, ensuring that the desired ratio of adhesive and catalyst is maintained. In addition, level sensors and automatic filling control simplify operation, while the liter of silica gel in the catalyst tank ensures protection against moisture.

The I-AMX is not only compact and easy to use, but also provides accurate data on the amount of adhesive used, enabling efficient resource management. With the ability to mix small quantities in real time, this equipment minimizes waste and maximizes the efficiency of the lamination process.