Squeegee cameras for the printing industry

Squeegee cameras for the printing industry

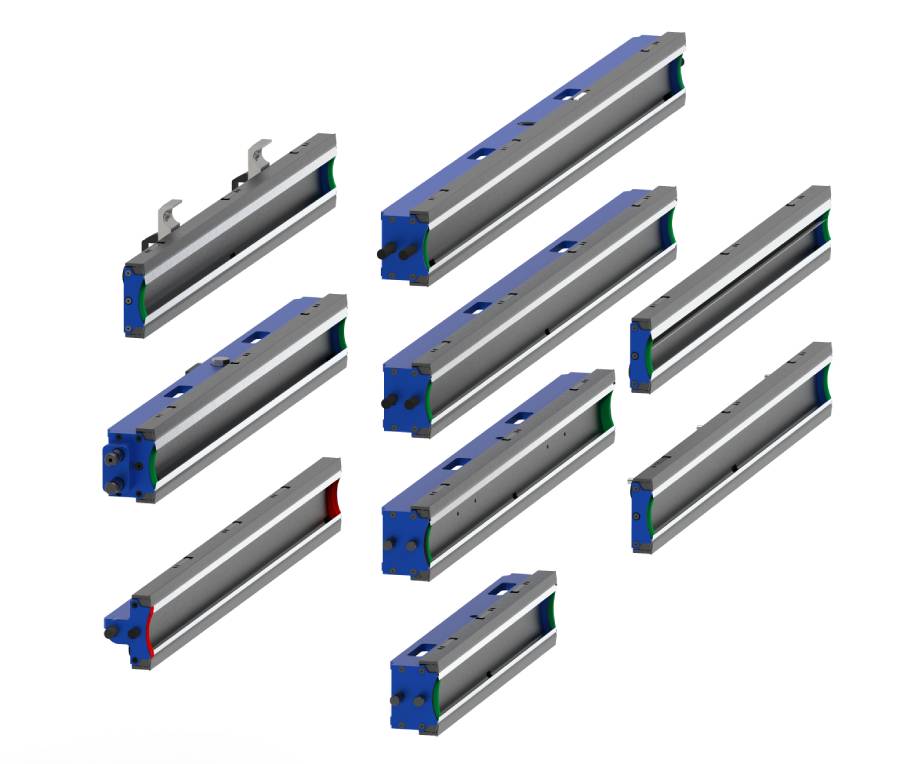

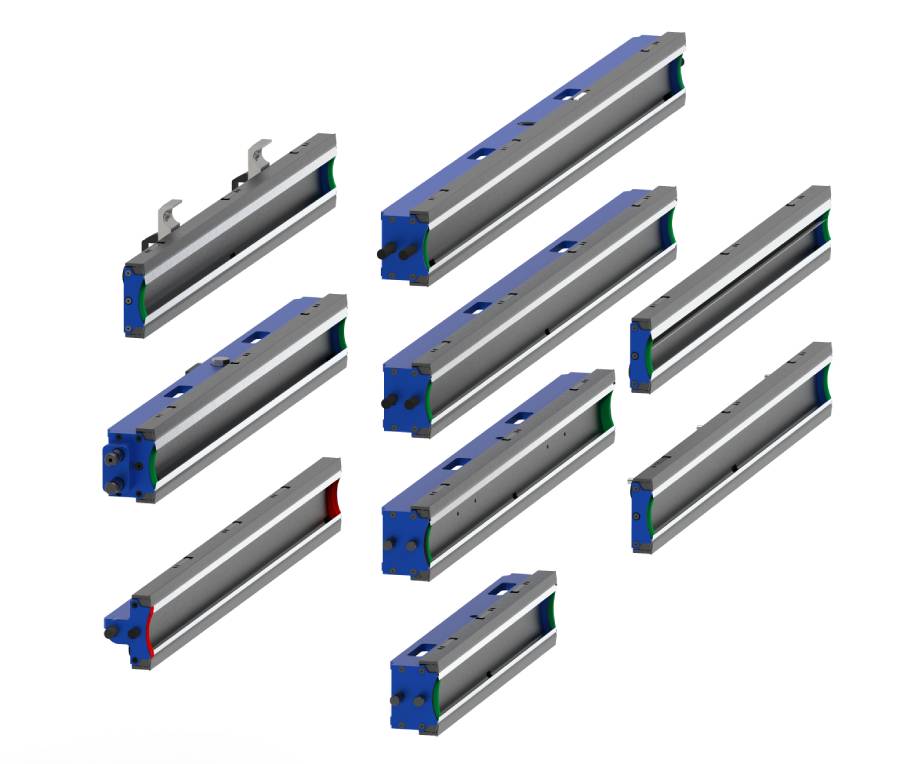

I-DBC squeegee chambers for flexography

Ultra-light, rugged and easy to mount without tools.

Contact us now and discover the model that best suits your needs.

Receive in your email the dossier with the complete technical information

Receive in your email the dossier with the complete technical information

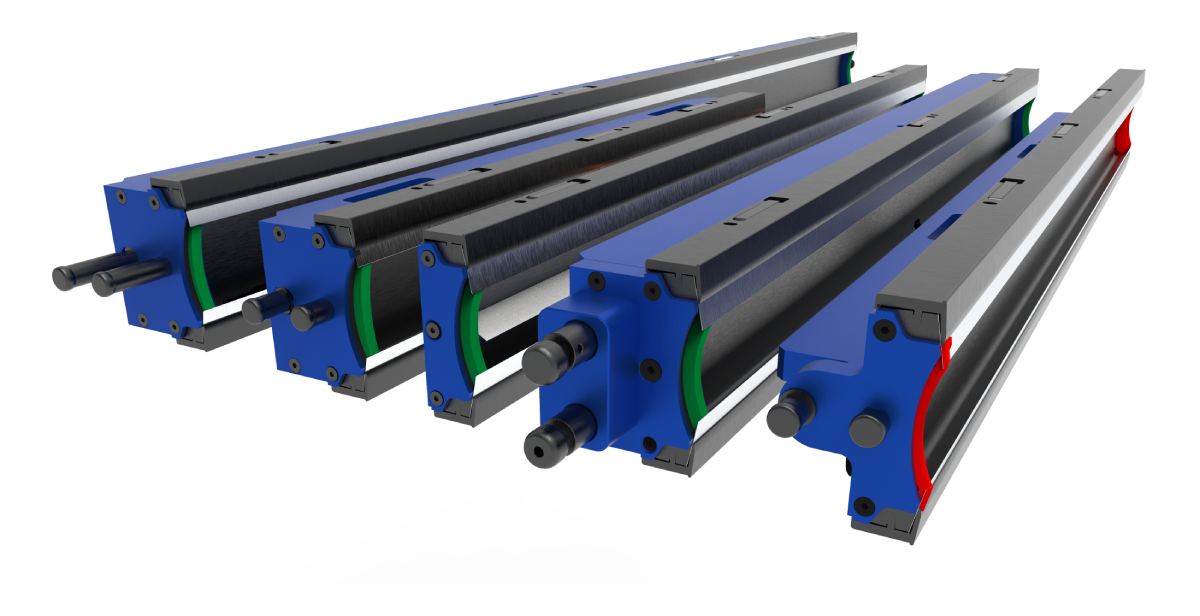

I-DBC doctor blade chambers represent an advanced solution for the flexo industry, the result of a meticulous design and improvement process based on common challenges identified by Inelme’s printing industry professionals. These chambers are made of extruded and anodized aluminum, making them ultra-lightweight and highly resistant to bending and corrosion.

The ergonomic design allows tool-free assembly, facilitating the process with a simple movement. In addition, the hinged heads and tabs located on the edges of the chambers allow for quick and easy change and adjustment of the scrapers, optimizing time and reducing operating efforts.

The chamber is characterized by its robustness and light weight, which not only ensures uniform cleaning of the anilox roller but also long product durability. Its adaptability to almost any printer makes it a versatile and economical choice for flexo printing professionals.

Squeegee cameras for the printing industry

| Model | Functionality | Description |

|---|---|---|

| I-DBC | Camper chamber assembly for flexo printing machine without holder |

Custom-built chamber made of 25-micron hard-anodized extruded aluminum. Quick blade change system with mechanical clamping by means of folding jaws and clamping levers. Foam side seals, quick change without tools. Includes 2 replacement side shutters per camera. |

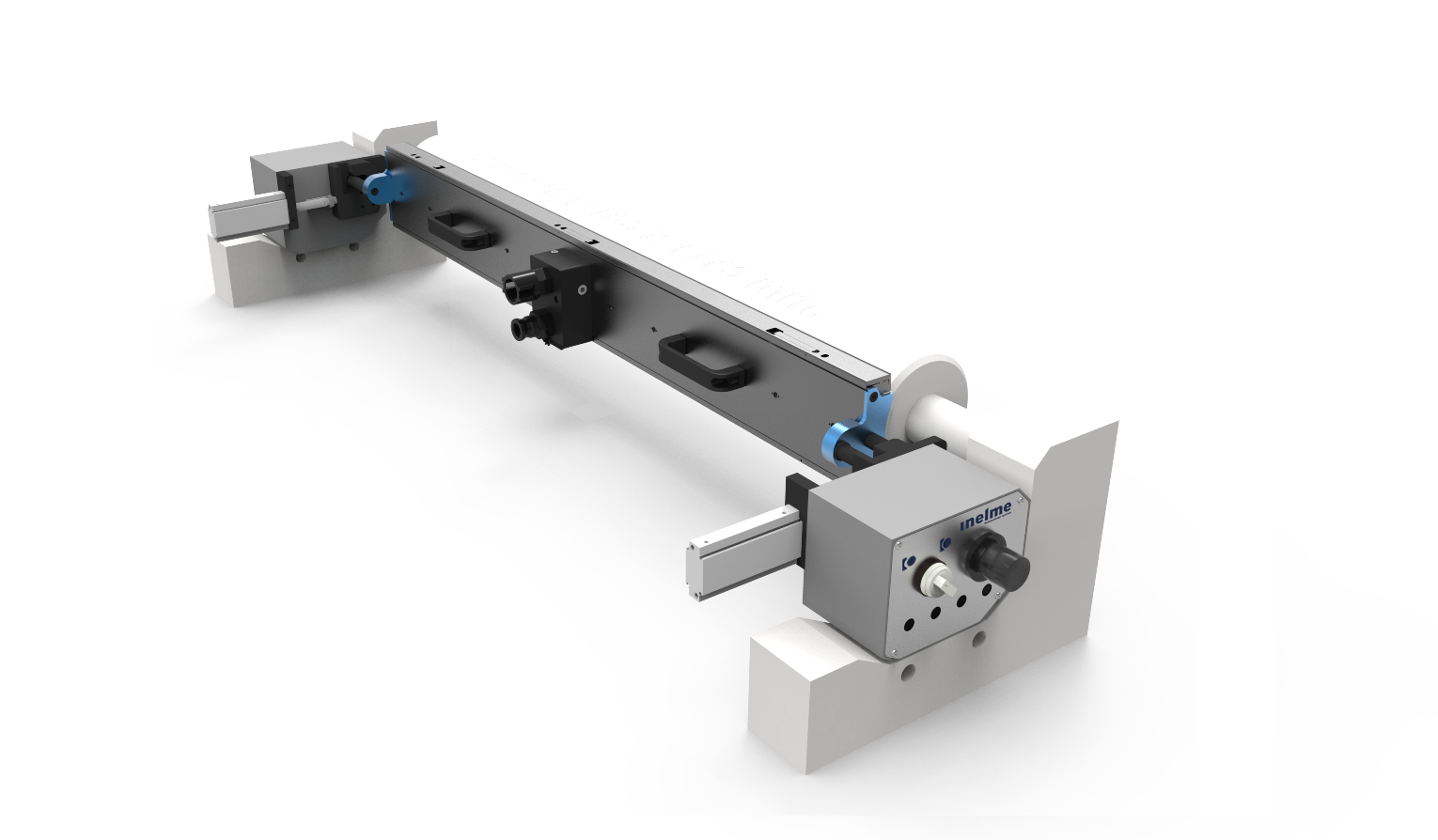

| I-DBC Multi S | Flexo doctor blade chamber assembly with stand and skids |

Custom-built chamber in extruded aluminum. Complete support with low friction pneumatic drive. Box with pneumatic regulator and switch for approach. Includes 2 replacement side shutters per camera. Chamber with 3 blades. |

| I-DBC Multi | Cam Squeegee Chamber without holder for flexo printing presses |

Custom-built chamber made of 25-micron hard-anodized extruded aluminum. Quick blade change system with mechanical clamping by means of folding jaws and clamping levers. Includes 2 replacement side shutters per camera. Chamber with 3 blades. |