Flexography and gravure

Laser anilox roll cleaning system

Inelme offers you the technology and solutions that your printing machines need to reach the optimal performance point.

Sistemas Inelme is the leading manufacturer of systems and solutions for the printing industry, specializing in Flexography and Gravure. For more than 15 years we have been designing the most effective solutions for your printing equipment to maintain an optimal and constant performance. Today we are present in more than 40 countries on five continents. Graphic companies have trusted and continue to do so because our solutions are manufactured with proven quality components to give maximum performance to their printing equipment and use the most advanced technology on the market.

What solution do you need?

- Cleaning anilox cylinders

- Transportation or storage of anilox

- Control, mixing, distribution, dosing, filtering and/or cleaning of inks

- Lamination adhesive mixers

- Doctor blade chambers

- Consumables

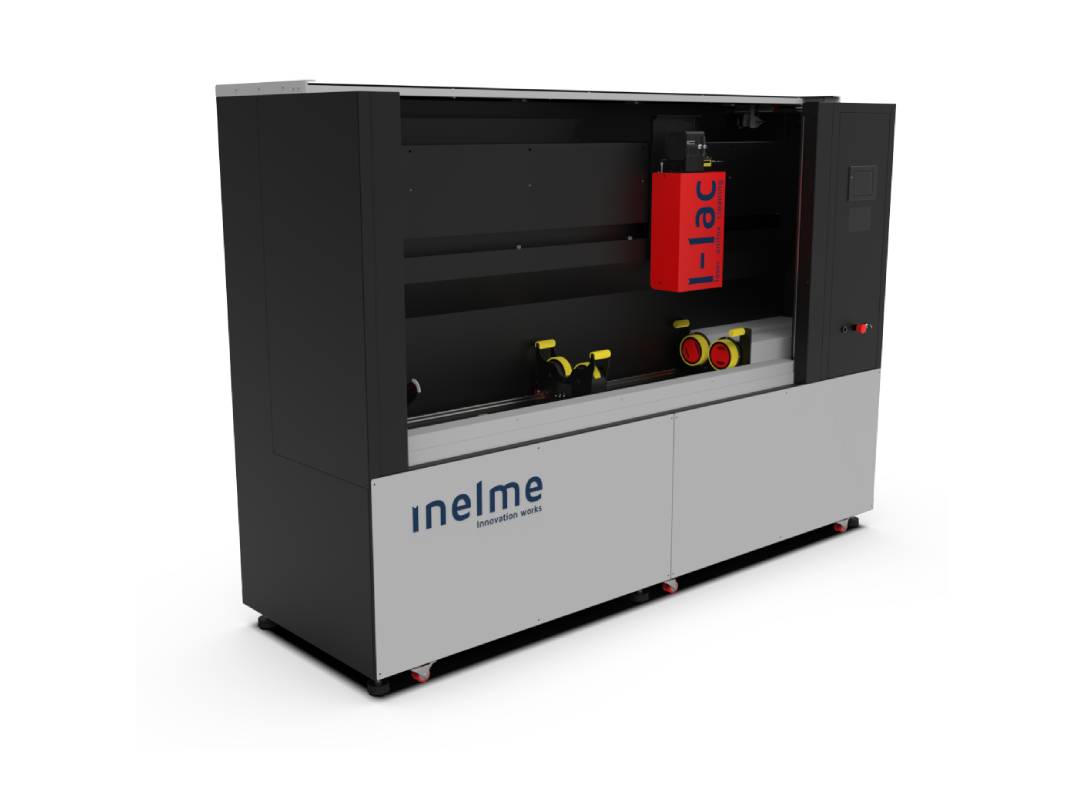

Anilox cleaning

Deep, damage-free, sequential, fast, portable and precise laser cleaning for anilox.

Request information

Laser cleaning of anilox cylinders →

Laser cleaning of anilox cylinders

Vertical and sequential laser cleaning of anilox

Vertical and sequential laser cleaning of aniloxes →

Portable anilox roll washing machine →

Portable anilox roll washing machine

Anilox cleaning cart and doctor blade chambers

Anilox cleaning cart and doctor blade chambers

Anilox storage and transportation

Transport and store safely and efficiently, preventing damage to your anilox sleeves.

Request information

Storage of sleeves, shirts, cliché holders and aniloxes →

Anilox sleeve and sleeve transport trolley →

Transport and cleaning of anilox and doctor blade chambers →

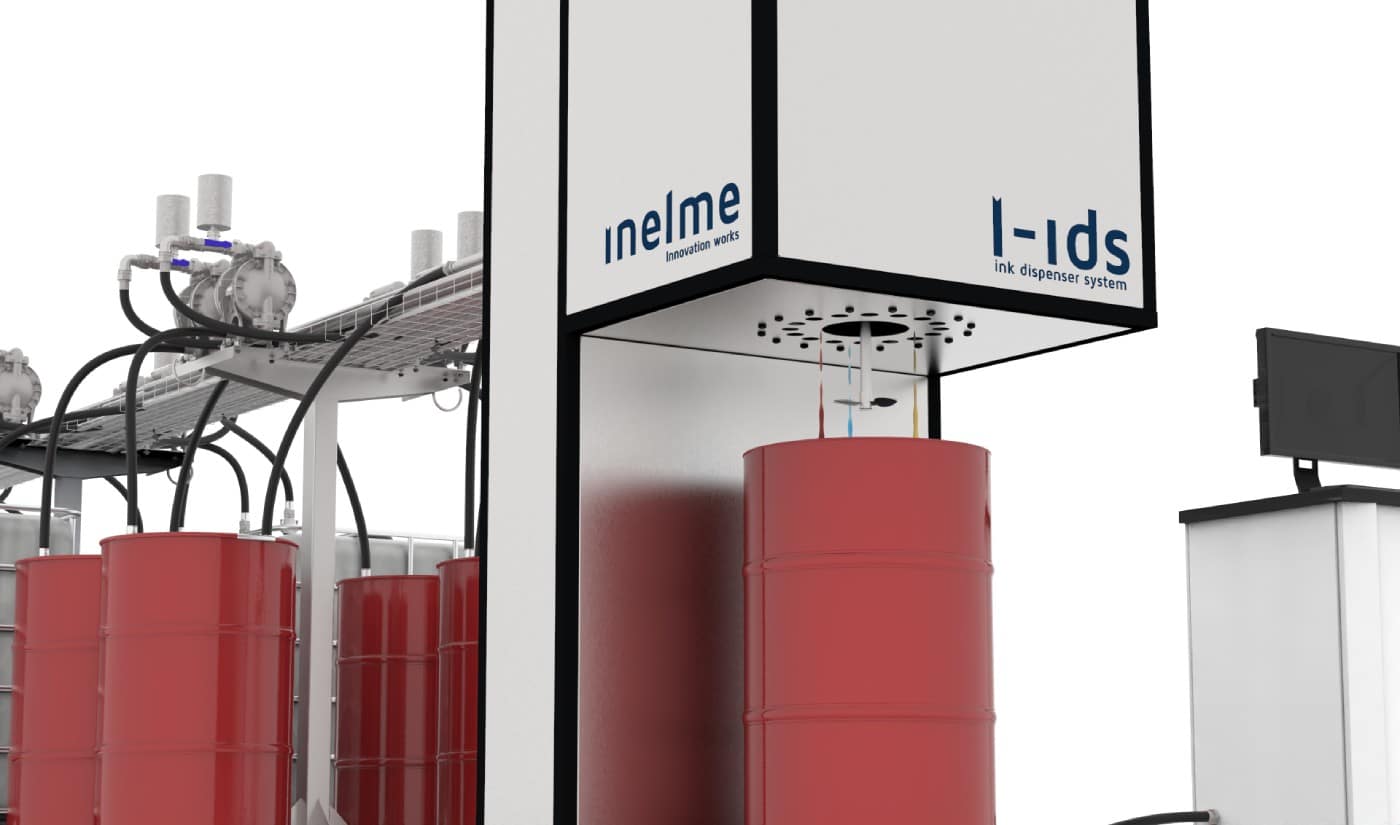

Ink management

Control, mixing, distribution, filtering and cleaning of inks.

Request information

Automatic ink washing system →

Centralized ink control system →

Ink dispenser →

Non-stop ink filtering →

Pneumatic pump for transferring fluids →

Automatic ink dosing system →

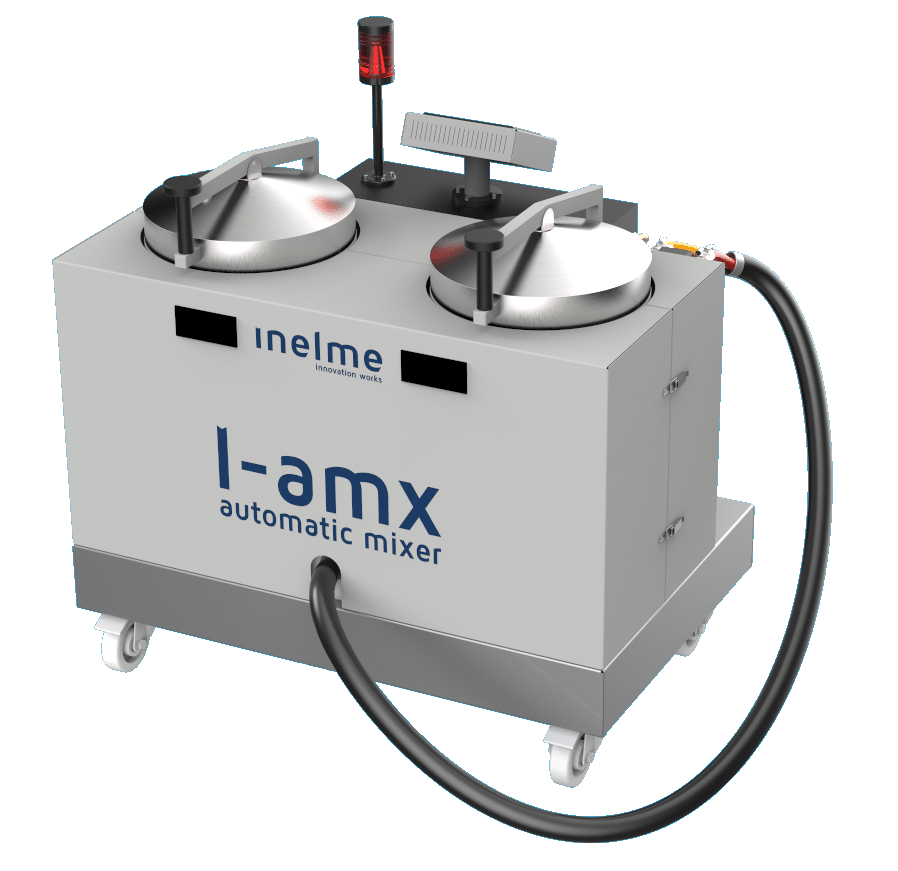

Lamination

Lamination adhesive mixers. With and without solvents.

Request information

Adhesive mixer for solvent-free lamination →

Adhesive mixer for solvent lamination →

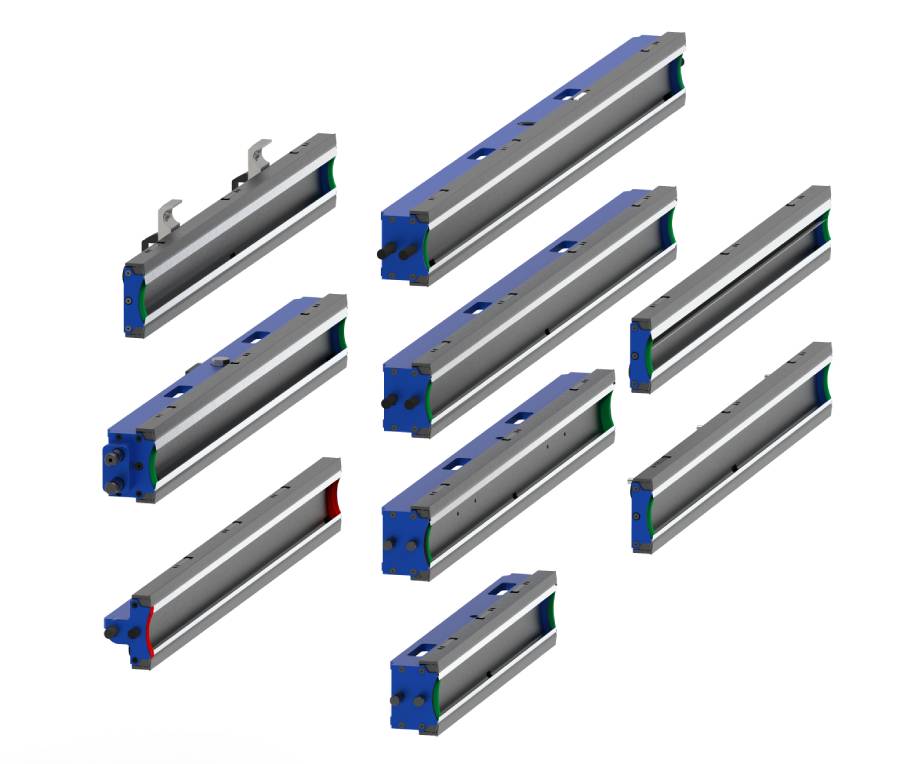

Doctor blade chambers

Ultralight, resistant and easy to assemble on a machine without the use of tools.

Request information

Flexo squeegee chambers →

Consumables

Wide range of products for professional printing equipment.

Request information

Plastic blades, steel, anilox, ceramic, chemical… →