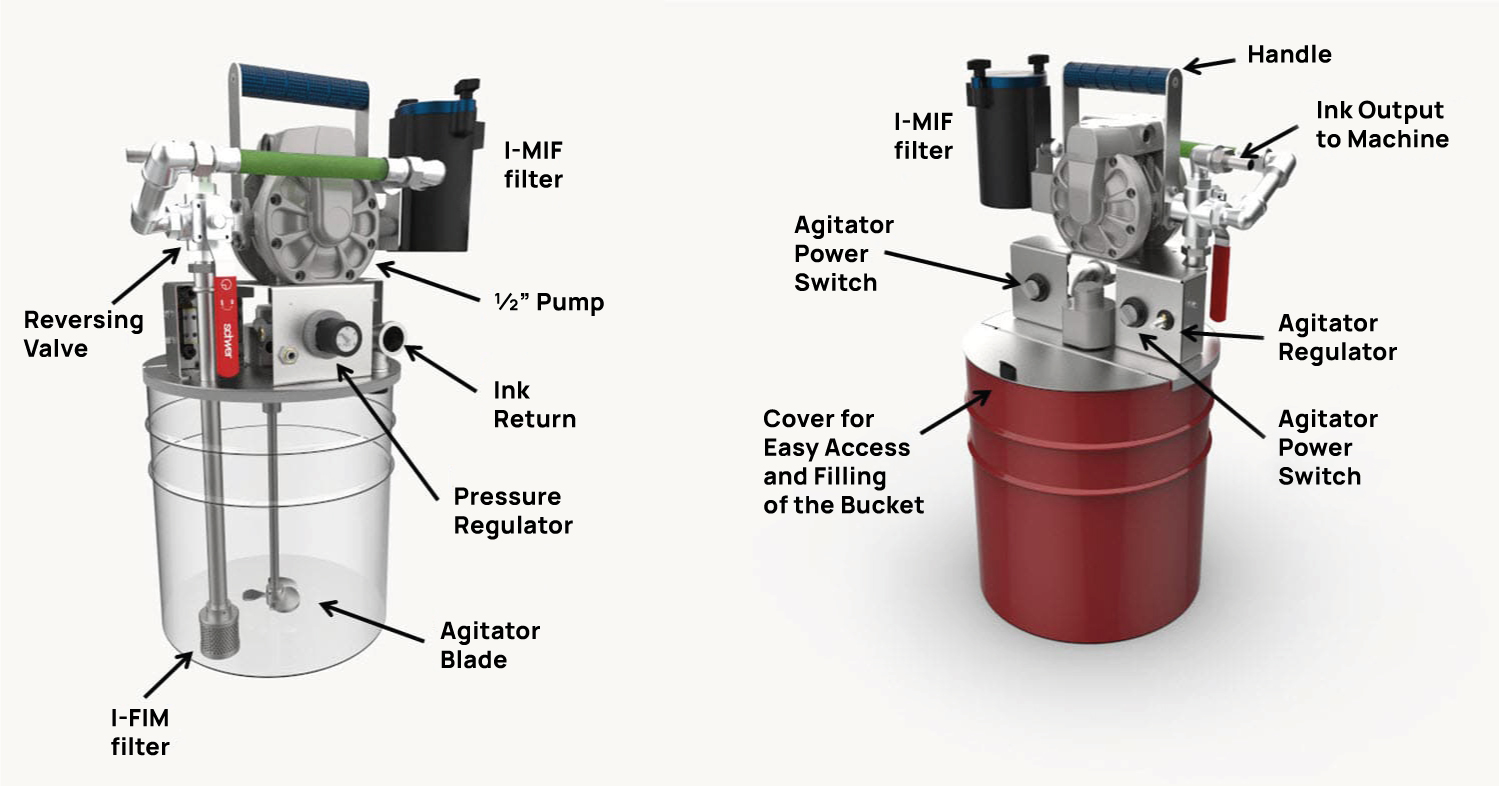

I-NPU Pneumatic pump

Laser anilox roll cleaning system

With stirrer, filters and flow reversal

Tell us your contact information and receive professional advice without obligation.

I-NPU guarantees homogeneity in the transfer of fluids

SAVING 80 % OF TIME

ALVEOLS AT 100% PERFORMANCE

ANILOX CLEANING WITH OR WITHOUT SHAFT

LASER OPTIMIZED FOR FLEXOGRAPHY

The pneumatic pump system is a tool that allows pumping liquids taking into account their viscosity, density or with solid particles in suspension. Its operation is based on the impulsion of the fluid from the alternating movement of its pneumatically driven double diaphragm.

The pneumatic pump system consists of the following elements:

– Pneumatic pump Pneumatic supply is made through the 8 mm pneumatic tube connector mounted at the rear, next to the pressure regulator. – Pneumatic agitator Designed for agitation and/or mixing of different liquids. – Ink bucket The commonly used bucket is placed with the assembly at the bottom so that the absorption rod and agitator are immersed in the ink.

Receive in your email the dossier with the complete technical information

Optionally it can include:

Magnetic filter: This element filters the ink by removing solid particles. Pneumatic switch: The equipment has a pneumatic switch to activate and deactivate the pump located at the front, on the left side. Reversing valve: This valve is used to reverse the flow direction of the pump.

Up to 80% time savings when cleaning Anilox cylinders with I-Lac machines

Cleaning anilox cylinders has always been one of the biggest concerns for flexo printers. If the cylinders are not perfectly clean, their transfer capacity is reduced and therefore the color intensity of the print is lost, with the consequences for the production that this can have: invalid prints, longer start-up times, etc. I-LAC solves this problem effectively thanks to the laser that removes the dried ink from the inside of the cells without damaging the cylinder cells. A specially designed optical laser vaporizes any residue and cleans away dried ink, adhesives, waxes, silicones, etc. Laser technology allows cleaning without exerting any mechanical or thermal action on the anilox cylinder, which allows us to clean even after each use and preserve the useful life of the anilox rollers for much longer.

We have I-LAC machines with measurements from 500 mm in length to 3500 mm (cylinder without shafts), and special measurements can be adapted according to needs.

|

Model |

Maximum cleaning length (cylinder without shafts): |

Minimum cylinder diameter: |

Maximum cylinder diameter: |

|

I-LAC F60- 6 |

600 mm |

Ø55 mm |

Ø200 mm |

|

I-LAC F60 – 10 |

1000 mm |

Ø110 mm |

Ø300 mm |

|

I-LAC F60 – 15 |

1500 mm |

Ø110 mm |

Ø300 mm |

|

I-LAC F60 – 20 |

2000 mm |

Ø110 mm |

Ø300 mm |

|

I-LAC F60 – 25 |

2500 mm |

Ø110 mm |

Ø300 mm |

|

I-LAC F60 – 30 |

3000 mm |

Ø110 mm |

Ø300 mm |

|

I-LAC F60 – 35 |

3500 mm |

Ø110 mm |

Ø300 mm |

Receive in your email the dossier with the complete technical information

I-NPU.PUMPPNEUMATICS

With stirrer, filters and flow inverter

Join the technological revolution in welding and cutting.

Contact us for more information.

Optionally it can include: Magnetic filter: This element filters the ink by removing the solid particles found. Pneumatic switch: The equipment has a pneumatic switch to activate and deactivate the pump located at the front, on the left side. Reversing valve: This valve is used to reverse the flow direction of the pump.

Receive in your email the dossier with the complete technical information

[gravityform id=”17″ title=”true” description=”true”]